FloMaster®

Circular Bin DischargeDescription

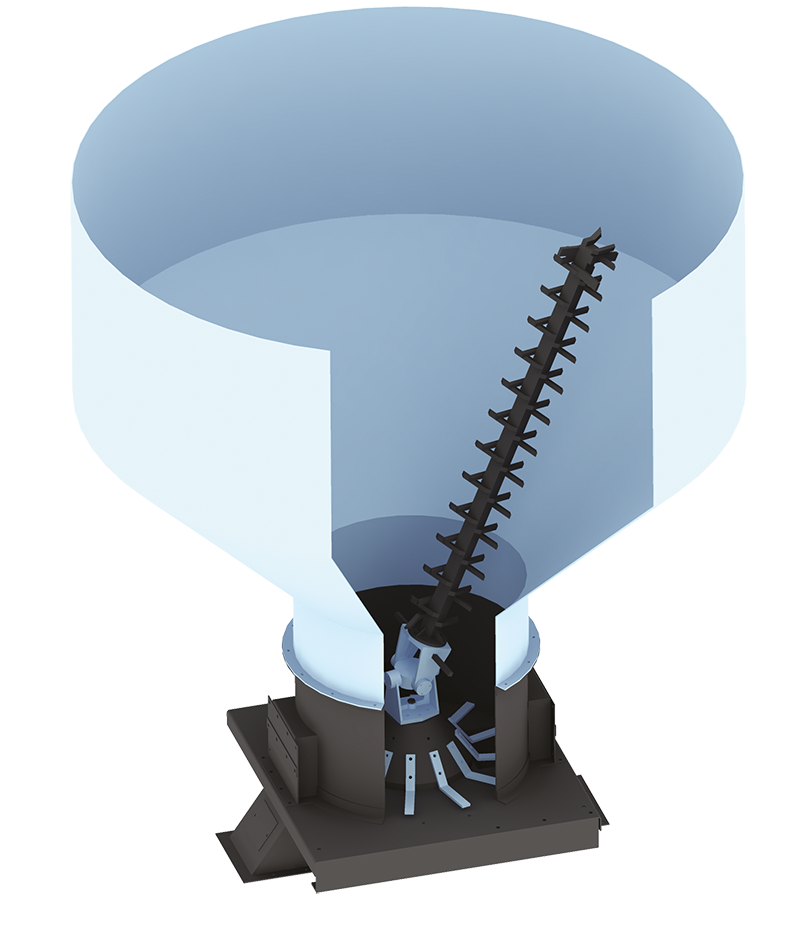

The FloMaster® Circular Bin Discharger (CBD) is a well proven and established positive discharge aid for hoppers and silos where the material is to be handled has characteristics which make it difficult

to discharge or control.

A rotating arch breaker arm travels around the hopper bottom section of the silo breaking any bridge of material which may have formed.

This ensures a flow of material to the discharger which can be supplied as a single, two or three stage unit to suit the characteristics of the material to be handled and the through-puts required.

The standard range comprises of two sizes:

800mm and 1000mm diameter.

Besides functioning as a bin discharger, the FloMaster® can be used to maintain a head of normalised material in the outlet chute, thus assisting the accuracy of subsequent metering or weighing equipment. Material in excess of the take away rate is recycled.

The FloMaster® is driven by a single drive controlling the rotation of both the discharger and arch breaker arm.

Actual drive arrangements vary according to the application or customer requirements.

Features and Benefits

Movement of the chain when buried in the material will induce the whole mass to move forward gently in a solid column. The Eleveyor design permits the column of material to be moved vertically or on an inclined plane. Eleveyors are manufactured in a standard range of sizes from 200mm wide upwards, which enables them to meet every requirement.

Positive Discharge

Archbreaker arm is immersed within the material to be discharged promoting positive flow.

Compact

The FloMaster® forms an integral part of the silo and occupies minimal space.

Versatile

Can control the discharge of non free flowing materials and those subject to fluidisation.

Cost Effective

Simple design ensures cost effective solution to discharge problems.

Safe

All moving parts are totally enclosed.

Minimal Wear

Machines operate at slow speeds for long life.

Quiet

Operation is virtually silent making the unit environmentally acceptable.

Easily Maintained

Main shaft assembly removed from below.

Unique

The FloMaster® is a unique Schenck Process product and has been proven over 50 years.

Totally Enclosed

Unit is totally enclosed ensuring dust tight operation.

Address

Redler Limited

Unit 102 Stonehouse Business Park,

Sperry Way, Stonehouse, Gloucestershire, GL10 3UT, United Kingdom

Phone

T: +44 (0) 1453 704300